-

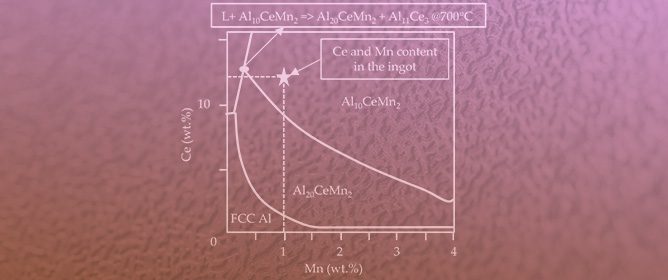

Solidification Kinetics of an Al-Ce Alloy with Additions of Ni and Mn

Solidification Kinetics of an Al-Ce Alloy with Additions of Ni and Mn -

Influence of Flow-Gas Composition on Reaction Products of Thermally Treated NMC Battery Black Mass

Influence of Flow-Gas Composition on Reaction Products of Thermally Treated NMC Battery Black Mass -

Determination of Corrosion Resistance of High-Silicon Ductile Iron Alloyed with Nb

Determination of Corrosion Resistance of High-Silicon Ductile Iron Alloyed with Nb -

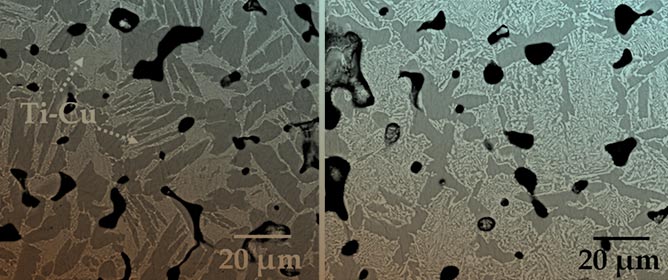

Powder Metallurgy Fabrication and Characterization of Ti6Al4V/xCu Alloys for Biomedical Applications

Powder Metallurgy Fabrication and Characterization of Ti6Al4V/xCu Alloys for Biomedical Applications -

Impact of Ti Doping on the Microstructure and Mechanical Properties of CoCrFeMoNi High-Entropy Alloy

Impact of Ti Doping on the Microstructure and Mechanical Properties of CoCrFeMoNi High-Entropy Alloy

Journal Description

Metals

Metals

is an international, peer-reviewed, open access journal published monthly online by MDPI. The Portuguese Society of Materials (SPM), and the Spanish Materials Society (SOCIEMAT) are affiliated with Metals and their members receive a discount on the article processing charges.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within Scopus, SCIE (Web of Science), Inspec, CAPlus / SciFinder, and other databases.

- Journal Rank: JCR - Q2 (Metallurgy & Metallurgical Engineering) / CiteScore - Q1 (Metals and Alloys)

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 15 days after submission; acceptance to publication is undertaken in 2.7 days (median values for papers published in this journal in the first half of 2023).

- Recognition of Reviewers: reviewers who provide timely, thorough peer-review reports receive vouchers entitling them to a discount on the APC of their next publication in any MDPI journal, in appreciation of the work done.

- Companion journals for Metals include: Compounds and Alloys.

Impact Factor:

2.9 (2022);

5-Year Impact Factor:

2.9 (2022)

Latest Articles

Role of Precipitates on the Grain Coarsening of 20CrMnTi Gear Steel during Pseudo-Carburizing

Metals 2023, 13(8), 1422; https://doi.org/10.3390/met13081422 - 08 Aug 2023

Abstract

The carburizing period for tool steel could be significantly shortened by operating at a higher carburizing temperature. However, grain coarsening happens during the carburizing process, and then results in the deteriorated surface properties in 20CrMnTi gear steel, especially at an elevated carburizing temperature.

[...] Read more.

The carburizing period for tool steel could be significantly shortened by operating at a higher carburizing temperature. However, grain coarsening happens during the carburizing process, and then results in the deteriorated surface properties in 20CrMnTi gear steel, especially at an elevated carburizing temperature. The relationships between grain coarsening and the precipitates in the developed 20CrMnTi gear steel during pseudo-carburizing were established by microstructure characterization, precipitate analysis and in-situ observation to clarify the coarsening mechanism. The results manifested the Baker–Nutting orientation relationship between the (Ti, Mo)(C, N) particles and the matrix, and then testified to the redissolution and ripening of the (Ti, Mo)(C, N) precipitates pre-formed in the α phase during the carburizing. Coarsening in austenite grain during the carburizing process was mainly caused by the rapid redissolution and ripening of the (Ti, Mo)(C, N) precipitates, although this occurred in a very short pseudo-carburizing time. The area density of the dispersed unripe (Ti, Mo)(C, N) particles markedly decreased from 0.389% in as-hot rolled gear steel to 0.341%, and then from 0.279% in carburized steels at 970 and 980 °C, respectively. Additionally, the redissolution and ripening of the (Ti, Mo)(C, N) precipitates were accelerated by the elevated carburizing temperature of 980 °C, at which time the growing rate in austenite grains was 2.34 μm/min during the prior 1 min (0.79 μm/min during the prior 3 min at 970 °C). The temperature then decreased to 0.003 μm/min in the subsequent carburizing process. The results obtained our current work reflected that the particles with excellent thermal stability should play important roles in the limitation of grain coarsening during the carburizing process.

Full article

(This article belongs to the Special Issue Novel Steel Compositions and Processing Technologies)

Open AccessArticle

Grain Growth during Mechanical Processing of Austenitic Stainless Steel AISI 321

by

, , , , and

Metals 2023, 13(8), 1421; https://doi.org/10.3390/met13081421 - 08 Aug 2023

Abstract

The kinetics of austenite grain growth during thermomechanical treatment of AISI 321 steel with a relatively high content of carbon (0.07 wt. %) and titanium (0.50 wt. %) were studied. Hot deformation was carried out by the uniaxial compression of cylindrical specimens on

[...] Read more.

The kinetics of austenite grain growth during thermomechanical treatment of AISI 321 steel with a relatively high content of carbon (0.07 wt. %) and titanium (0.50 wt. %) were studied. Hot deformation was carried out by the uniaxial compression of cylindrical specimens on a Gleeble 3800 thermomechanical simulator. A dependence is obtained for calculating the kinetics of austenite grain growth for a temperature range of 1150–1250 °C. The proposed dependence makes it possible to evaluate grain growth under non-isothermal conditions. The verification of the adequacy of the proposed dependence and the method for calculating the grain size at cooling rates 0.2, 1 and 5 °C/s showed its high convergence. The difference between the calculated and experimental grain size did not exceed 8%. The suppression of grain growth is due to the precipitation of titanium carbides and carbonitrides. Using the developed grain growth model, an analysis was made of the reasons for the formation of large grains in the shell after the elongating in the production process.

Full article

(This article belongs to the Section Metal Casting, Forming and Heat Treatment)

►▼

Show Figures

Figure 1

Open AccessArticle

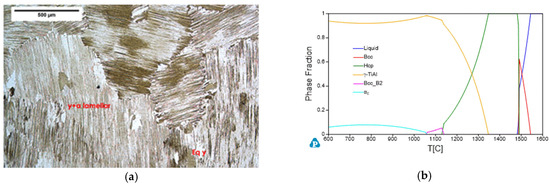

Improving Forging Outcomes of Cast Titanium Aluminide Alloy via Cyclic Induction Heat Treatment

Metals 2023, 13(8), 1420; https://doi.org/10.3390/met13081420 - 08 Aug 2023

Abstract

The objective of this research was to improve the forging outcome of peritectic solidifying cast titanium aluminide (TiAl) 4822 alloy (Ti-48Al-2Nb-2Cr at.%) in hot isostatic pressed and homogenised (HH) condition using cyclic induction heat treatment (CHT). This study adds to research around CHT

[...] Read more.

The objective of this research was to improve the forging outcome of peritectic solidifying cast titanium aluminide (TiAl) 4822 alloy (Ti-48Al-2Nb-2Cr at.%) in hot isostatic pressed and homogenised (HH) condition using cyclic induction heat treatment (CHT). This study adds to research around CHT for TiAl alloys by applying industrially relevant induction heating to conduct five heating cycles at the single αphase temperatures (1370 °C) necessary for grain refinement. Two cooling rates were explored in each cycle, air cooling (ACCHT) and controlled furnace-like cooling (FCCHT), without returning to room temperature. Samples were assessed at each stage in terms of their morphologies, lamellar grain size and content, as well as phase and dynamic recrystallised fraction, and subsequent primary and secondary compression behaviour with uniaxial isothermal compression. The FCCHT process resulted in a homogeneously refined fully lamellar microstructure, and ACCHT, in a heterogeneous microstructure consisting of lamellar and feathery γ (γf) at differing fractions across the piece, depending on the cooling rate compared with HH. The results show that CHT improved forging outcomes for both compression stages investigated, resulting in uniform compression samples with higher volumes of dynamic recrystallised material compared with the instability seen with the compression of HH material.

Full article

(This article belongs to the Special Issue Microstructure and Properties of Intermetallics)

►▼

Show Figures

Figure 1

Open AccessFeature PaperArticle

Statistically Modeling the Fatigue Life of Copper and Aluminum Wires Using Archival Data

Metals 2023, 13(8), 1419; https://doi.org/10.3390/met13081419 - 08 Aug 2023

Abstract

It has been known for at least 150 years that fatigue life data exhibits a considerable amount of variability. Furthermore, statistically modeling fatigue life adequately is challenging. Different empirical approaches have been used, each of which has merit; however, none is appropriate universally.

[...] Read more.

It has been known for at least 150 years that fatigue life data exhibits a considerable amount of variability. Furthermore, statistically modeling fatigue life adequately is challenging. Different empirical approaches have been used, each of which has merit; however, none is appropriate universally. Even when a sufficiently robust database exists, the scatter in the fatigue lives may be extremely large and difficult to characterize. The purpose of this work is to review traditional and more modern empirically based methodologies for estimating the statistical behavior of fatigue data. The analyses are performed on two historic sets of data for annealed aluminum wire and annealed electrolytic copper wire tested in reverse torsion fatigue. These data are readily available In publications. Specifically, the review considers a traditional method for stress-cycle (S-N) analysis which includes linear regression through load dependent medians and mean square error (MSE) confidence bounds. Another approach that is used is Weibull distribution estimation for each loading condition, from which estimations for the median behavior and confidence bounds are determined. The preferred technique is the development of a cumulative distribution functions for fatigue life, which contains aspects of traditional reliability, classical S-N, and applied loading modeling. Again, confidence bounds are estimated for this technique. Even though it is an empirical technique, there are mechanistic aspects that underlie the empiricism. This approach is suggested because the method is very robust, and the estimation is more accurate than the other methods.

Full article

(This article belongs to the Special Issue Metal Fatigue Failure: Mechanism, Theories and Design)

►▼

Show Figures

Figure 1

Open AccessArticle

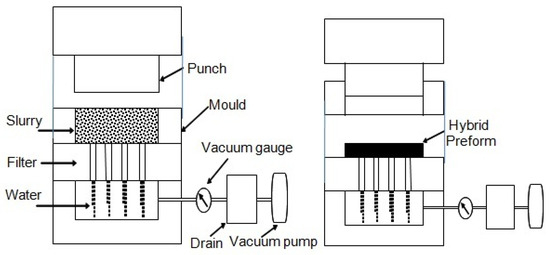

Statistical Analysis of Tribological Properties of Mg(AM50)/GNF-Al2O3sf Hybrid Composites

Metals 2023, 13(8), 1418; https://doi.org/10.3390/met13081418 - 08 Aug 2023

Abstract

The present article describes the tribological properties of Mg-based hybrid composites reinforced with graphite nanofiber (GNF) and alumina short fiber (Al2O3sf) that were investigated. The Mg/GNF/Al2O3sf hybrid composites with varying volume fraction of fiber (10 vol.%,

[...] Read more.

The present article describes the tribological properties of Mg-based hybrid composites reinforced with graphite nanofiber (GNF) and alumina short fiber (Al2O3sf) that were investigated. The Mg/GNF/Al2O3sf hybrid composites with varying volume fraction of fiber (10 vol.%, 15 vol.%, 20 vol.%) were developed. SEM observations indicate that the GNF cluster distributions within the array of the Al2O3sf network are found to be relatively good. The Taguchi design of the experiment has been applied to conduct the wear test, and the statistical analysis of variance (ANOVA) has been used to evaluate the influence of wear test parameters on the wear loss and coefficient of friction (COF) of the composites. The influence of wear test parameters such as volume fraction of fiber (VF), applied load (AL), sliding distance (SD), and sliding speed (SP) on the wear loss and COF of composites was analyzed under dry sliding conditions. The results of ANOVA indicate that the sliding distance was found to be the prominent factor affecting wear loss, and the applied load influenced the COF most significantly. Furthermore, the composites with 20 vol.% of fiber had lower wear loss than those with 10 vol.% and 15 vol.% of fiber. The COF of composites with 15 vol.% of fiber was found to be slightly lower compared to the 10 vol.% and 20 vol.% of fiber cases. The results imply that the hybridization of GNFs and Al2O3sf, as well as the formation of Mg17Al12 and Al2MgC2 precipitates enhanced the tribological properties of the Mg hybrid composites.

Full article

(This article belongs to the Topic Metal Matrix Composites: Recent Advancements)

►▼

Show Figures

Figure 1

Open AccessArticle

Microstructure Evolution and Growth of Interfacial Intermetallic Compounds in NiCr/Ti Alloy Laminated Composite after Explosive Welding and Heat Treatment

Metals 2023, 13(8), 1417; https://doi.org/10.3390/met13081417 - 08 Aug 2023

Abstract

►▼

Show Figures

The paper considers the issues of interaction of the molten metal at the interface of explosively welded NiCr/titanium alloy laminated composites with the reaction zone formed during heat treatment, as well as the features of its destruction after welding. It was established that

[...] Read more.

The paper considers the issues of interaction of the molten metal at the interface of explosively welded NiCr/titanium alloy laminated composites with the reaction zone formed during heat treatment, as well as the features of its destruction after welding. It was established that the molten metal is a heterogeneous mixture based on Ni(Cr,Ti) and Ti(Ni,Al) solid solutions and NiTi and Ni3Ti intermetallic compounds. The estimated existence time of molten metal areas in the liquid state was ~10−8–10−11 s. The obtained values are comparable with the time of the unloading wave arrival at the contact surface, which is the reason for the presence of fracture areas in the form of detachments on the fracture surface. Continuous nanometer-size interlayers with an amorphous structure, due to the ultra-high cooling rate of the liquid melt, induce viscous destruction of the interface. Heat treatment at temperatures of 700 and 850 °C led to the formation of a layered reaction zone at the NiCr/Ti boundary, consisting of interlayers of solid solutions based on Ti2Ni, TiNi, and TiNi3 intermetallic compounds, as well as inclusions of a Cr(Ti) solid solution. The diffusion flow gradient was predominantly directed into the titanium alloy.

Full article

Figure 1

Open AccessArticle

Process Setup and Boundaries of Wire Electron Beam Additive Manufacturing of High-Strength Aluminum Bronze

Metals 2023, 13(8), 1416; https://doi.org/10.3390/met13081416 - 08 Aug 2023

Abstract

In recent years, in addition to the commonly known wire-based processes of Directed Energy Deposition using lasers, a process variant using the electron beam has also developed to industrial market maturity. The process variant offers particular potential for processing highly conductive, reflective or

[...] Read more.

In recent years, in addition to the commonly known wire-based processes of Directed Energy Deposition using lasers, a process variant using the electron beam has also developed to industrial market maturity. The process variant offers particular potential for processing highly conductive, reflective or oxidation-prone materials. However, for industrial usage, there is a lack of comprehensive data on performance, limitations and possible applications. The present study bridges the gap using the example of the high-strength aluminum bronze CuAl8Ni6. Multi-stage test welds are used to determine the limitations of the process and to draw conclusions about the suitability of the parameters for additive manufacturing. For this purpose, optimal ranges for energy input, possible welding speeds and the scalability of the process were investigated. Finally, additive test specimens in the form of cylinders and walls are produced, and the hardness profile, microstructure and mechanical properties are investigated. It is found that the material CuAl8Ni6 can be well processed using wire electron beam additive manufacturing. The microstructure is similar to a cast structure, the hardness profile over the height of the specimens is constant, and the tensile strength and elongation at fracture values achieved the specification of the raw material.

Full article

(This article belongs to the Special Issue Electron-Beam Technology for High Performance Alloys, Metals and Powders)

►▼

Show Figures

Figure 1

Open AccessFeature PaperArticle

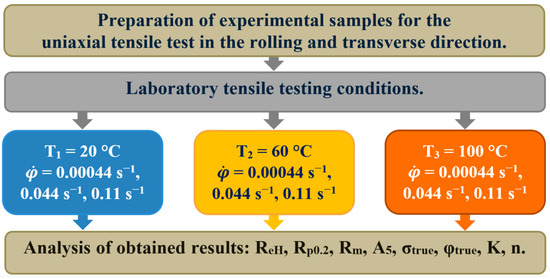

Effect of Preheating on the Mechanical Workability Improvement of High-Strength Electrical Steels during Tandem Cold Rolling

Metals 2023, 13(8), 1415; https://doi.org/10.3390/met13081415 - 08 Aug 2023

Abstract

Cold-rolled silicon steel strip products are widely used as the main soft magnetic components in cores of electrical motors, generators, and transformers. In the case of rotating electrical machines, the so-called non-oriented electro-technical steels are normally applied. They are characterized by a similar

[...] Read more.

Cold-rolled silicon steel strip products are widely used as the main soft magnetic components in cores of electrical motors, generators, and transformers. In the case of rotating electrical machines, the so-called non-oriented electro-technical steels are normally applied. They are characterized by a similar behaviour to the induced magnetic field found in all sheet plane directions. The kind of soft magnetic alloys that defined herein not only possess an isotropy of electromagnetic properties, but also high mechanical strength; such alloys are called high-strength electro-technical (HSET) steels. These commercially produced HSET steels contain a high silicon content in the range of 3–4 wt.%. However, if the silicon content exceeds 3%, the machinability of Fe–Si alloys is dramatically reduced and they become much more brittle as a consequence. According to this, regular hot band brittle damage occurs during cold deformation at a high-speed tandem rolling mill. In accordance with these reasons, the production of thin high-strength silicon steel grades using the traditional methods of cold rolling deformation is extremely problematic and it is characterised by a high degree of steel sheet mechanical damage. In this scientific work, the effect of preheating hot-rolled strips on their mechanical workability improvement during tandem cold rolling was investigated. The results of this study indicate that the cold rolling of hot bands at elevated temperatures increases their resistance to brittle failure and mechanical plasticity. Moreover, the mathematical simulation clearly demonstrates that residual stress is distributed relatively homogeneously across the thickness of samples, which were cold rolled at 100 °C in contrast to the same ones deformed at room temperature.

Full article

(This article belongs to the Special Issue Rolling Process of Metallic Materials)

►▼

Show Figures

Figure 1

Open AccessArticle

Two-Step Spin Forming of Thin-Walled Heads with Lateral Normal Flanged Holes

Metals 2023, 13(8), 1414; https://doi.org/10.3390/met13081414 - 08 Aug 2023

Abstract

►▼

Show Figures

A thin-walled head with a lateral normal flanged hole is a key part of a propellant tank, and its low-cost and high-precision forming process is very challenging. In this paper, a two-step method is proposed to preform the head via marginal-restraint mandrel-free spinning

[...] Read more.

A thin-walled head with a lateral normal flanged hole is a key part of a propellant tank, and its low-cost and high-precision forming process is very challenging. In this paper, a two-step method is proposed to preform the head via marginal-restraint mandrel-free spinning and then to realize the flanging of the lateral normal hole using a punching–spinning method. Finite element analysis of round-hole punching–spinning flanging shows that the larger the thinning ratio and the roller fillet radius, the lower the rebound and contour rise amount; the larger the feed ratio, the lower the rebound and the higher the contour rise amount. Further study on the effects of round-hole punching–spinning flanging on the secondary deformation of thin-walled heads shows that the deformation of the head in the area around the flanging hole is less severe than that of the flat blank, and the deformation in the circumferential direction is different from that in the busbar direction. Finally, it is verified through experiments that the two-step method can realize the spin forming of thin-walled heads with lateral normal flanged holes.

Full article

Figure 1

Open AccessArticle

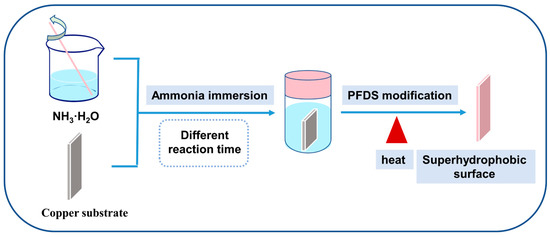

Effect of Microstructure on Coalescence-Induced Droplet Jumping Behavior of a Superhydrophobic Surface and Its Application for Marine Atmospheric Corrosion Protection

Metals 2023, 13(8), 1413; https://doi.org/10.3390/met13081413 - 07 Aug 2023

Abstract

Coalescence-induced droplet jumping behavior (CIDJB) refers to the spontaneous jumping of droplets on a specific superhydrophobic surface (SS) without any external energy, which offers a new approach to the field of marine atmospheric corrosion protection by isolating corrosive media. In this study, a

[...] Read more.

Coalescence-induced droplet jumping behavior (CIDJB) refers to the spontaneous jumping of droplets on a specific superhydrophobic surface (SS) without any external energy, which offers a new approach to the field of marine atmospheric corrosion protection by isolating corrosive media. In this study, a flower-like micro–nanocomposite structure SS (F-SS) and a sheet-like nanostructure SS (S-SS) were prepared on copper sheets by ammonia immersion and chemical vapor deposition. Firstly, we observed the microstructure characteristics of the samples and secondly analyzed its chemical composition and wettability. Moreover, the CIDJB was studied by simulated condensation experiments, and the influence of the microstructure on CIDJB was revealed. Meanwhile, the atmospheric corrosion resistance of samples was analyzed by electrochemical impedance spectroscopy (EIS) measurements, and the protection mechanism of SS through CIDJB was proposed. The results showed that the S-SS had a smaller solid–liquid contact area and lower interfacial adhesion, which is more conducive to CIDJB. Since a larger solid–liquid contact area requires greater interface adhesion energy for the droplets to overcome, droplet jumping behavior was not observed on the F-SS. Compared with the F-SS, the S-SS exhibited outstanding corrosion resistance due to the wettability transition of droplets by CIDJB, which facilitated the restoration of the air film to insulate the corrosive medium. The present study provides a reference for a marine atmospheric corrosion resistance technique through CIDJB on an SS.

Full article

(This article belongs to the Special Issue Editorial Board Members’ Collection Series: "Corrosion Protection and Prevention")

►▼

Show Figures

Figure 1

Open AccessArticle

Influence of Current Density upon Hydrogenation on the Shape Memory Effect of Binary TiNi Alloy Single Crystals

Metals 2023, 13(8), 1412; https://doi.org/10.3390/met13081412 - 07 Aug 2023

Abstract

Some results concerning the hydrogen effect at electrolytic saturation at a current density of j = 1500 and 3500 A/m2 for 3 h at room temperature on the temperature dependence of the yield stress σ0.1(T) and the shape

[...] Read more.

Some results concerning the hydrogen effect at electrolytic saturation at a current density of j = 1500 and 3500 A/m2 for 3 h at room temperature on the temperature dependence of the yield stress σ0.1(T) and the shape memory effect (SME) under tension of the [011]-oriented Ti-50.55%Ni (at.%) alloy single crystals are presented. It was shown that hydrogen is in a solid solution and forms particles of titanium hydride TiH2 after hydrogenation at j = 1500 and 3500 A/m2, respectively. Both hydrogen in the solid solution and TiH2 particles led to a decrease in the Ms temperature of the onset of the forward martensitic transformation (MT) upon cooling and the Md temperature (Md is the temperature at which the stresses for the onset of the stress-induced MT are equal to the stresses for the onset of plastic flow of the high-temperature B2 phase), and increased the yield stress σ0.1 of the B2 phase at the Md temperature compared to hydrogen-free crystals. It was found that the SME under stress depends on the tensile stress level and current density. The maximum SME εSME = 10 ± 0.2% at σex = 200 MPa and εSME = 10.5 ± 0.2% at σex = 300 MPa was observed in the hydrogen-free crystals and after hydrogenation at j = 1500 A/m2, respectively, which exceeded the theoretical value of lattice deformation ε0 = 8.95% for the B2-B19′ MT in [011] orientation under tension. At j = 1500 A/m2, the physical reason for the excess of the SME of the theoretical ε0 value was due to the increase in the plasticity of B19′ martensite upon hydrogenation. At j = 3500 A/m2, εSME = 8.0 ± 0.2%, and it was less than ε0 = 8.95% for B2-B19′ MT in [011] orientation under tension. The decrease in SME after hydrogenation at j = 3500 A/m2 was associated with the interaction of two types of B19′-martensite: oriented under stress and non-oriented, formed near TiH2 particles. It was shown that the redistribution of hydrogen in the bulk of the crystals during long-term holding for 168 h at 263 K after hydrogenation at j = 1500 A/m2 increases the SME relative to crystals without long-term holding: 3.5 times at 50 MPa and 1.8 times at 100–150 MPa. After long-term holding, εSME = 9.5 ± 0.2% at 150 MPa, which exceeds the theoretical value ε0 = 8.95% for B2-B19′ MT in [011] orientation under tension.

Full article

(This article belongs to the Special Issue Progress in and Prospects of Shape Memory Alloys)

►▼

Show Figures

Figure 1

Open AccessEditorial

Metal Recovery and Separation from Wastes

by

and

Metals 2023, 13(8), 1411; https://doi.org/10.3390/met13081411 - 07 Aug 2023

Abstract

With the development of society, large amounts of solid waste (slag, sludge, tailing, electronic waste, etc [...]

Full article

(This article belongs to the Special Issue Metal Recovery and Separation from Wastes)

Open AccessReview

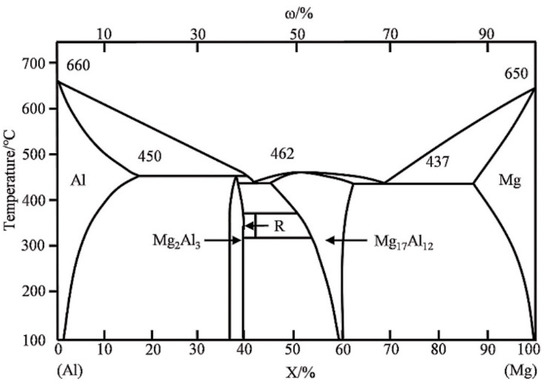

Solid-State Welding of Aluminum to Magnesium Alloys: A Review

Metals 2023, 13(8), 1410; https://doi.org/10.3390/met13081410 - 07 Aug 2023

Abstract

With the continuous improvement of lightweight requirements, the preparation of Mg/Al composite structures by welding is in urgent demand and has broad prospective applications in the industrial field. However, it is easy to form a large number of brittle intermetallic compounds when welding

[...] Read more.

With the continuous improvement of lightweight requirements, the preparation of Mg/Al composite structures by welding is in urgent demand and has broad prospective applications in the industrial field. However, it is easy to form a large number of brittle intermetallic compounds when welding Mg/Al dissimilar alloys, and it is difficult to obtain high-quality welded joints. The solid-state welding method has the characteristics of low energy input and high efficiency, which can inhibit the formation of brittle intermetallic compounds and help to solve the problem of the poor strength of welded joints using Mg/Al dissimilar alloys in engineering applications. Based on the literature of ultrasonic welding, friction welding, diffusion welding, explosive welding, magnetic pulse welding, and resistance spot welding of Al/Mg in recent years, this paper summarized and prospected the research status of solid-state welding using Mg/Al dissimilar alloys from three aspects: the optimization of welding parameters, the addition of interlayers, and hybrid welding process.

Full article

(This article belongs to the Special Issue Advanced Metal Welding and Joining Technologies)

►▼

Show Figures

Figure 1

Open AccessArticle

The Optimization of Welding Spots’ Arrangement in A-Pillar Patchwork Blank Hot Stamping

Metals 2023, 13(8), 1409; https://doi.org/10.3390/met13081409 - 06 Aug 2023

Abstract

With increasingly severe environmental problems, energy saving and environmental protection have become two important issues to be solved in the automobile industry. Patchwork blank hot-stamping technology can be used to obtain light-weight and high-strength parts and is thus increasingly used in the manufacture

[...] Read more.

With increasingly severe environmental problems, energy saving and environmental protection have become two important issues to be solved in the automobile industry. Patchwork blank hot-stamping technology can be used to obtain light-weight and high-strength parts and is thus increasingly used in the manufacture of autobody parts. Because the main blank and the patched blank need to be connected through spot welding before forming, the welding spots’ arrangement has a great influence on the formability of the part. In this study, a thermal–mechanical coupling finite element analysis model of A-pillar patchwork blanks was established. With the thickness of the patched blank, the distance between the welding spot and the external contour of the patched blank, and the number of welding spots as optimization variables, together with the maximum thinning rate and the maximum welding spot force as objectives, the influence of welding spot arrangement on forming quality was analyzed, and the welding spots’ arrangement was optimized using a central composite design (CCD), the response surface method (RSM), and the genetic algorithm (GA). The results showed that when the initial welding spot was located close to the contour of the patched blank, the bending moment was greater when the weld spot passed through the die corner, leading to the rupture of the welding spot or its surrounding base material due to the greater thinning rate. When the patched blank was thicker than the main blank, the main blank cracked during the forming process due to a greater increase in the thinning rate. The optimal solution of the weld spot arrangement on the A-pillar patchwork blanks was a 1.2 mm thick main blank, 0.8 mm thick patched blank, a distance of 29 mm between the weld spot and the contour line of the patched blank, and 16 weld spots. Hot-stamping experiments were conducted using the optimized weld spots’ arrangement, and high-quality parts were obtained.

Full article

(This article belongs to the Special Issue Hot Stamping Processing of Steel and Alloys)

►▼

Show Figures

Figure 1

Open AccessArticle

An Investigation of Spiral Dislocation Sources Using Discrete Dislocation Dynamics (DDD) Simulations

by

and

Metals 2023, 13(8), 1408; https://doi.org/10.3390/met13081408 - 06 Aug 2023

Abstract

Discrete Dislocation Dynamics (DDD) simulations are a powerful simulation methodology that can predict a crystalline material’s constitutive behavior based on its loading conditions and micro-constituent population/distribution. In this paper, a 3D DDD model with spiral dislocation sources is developed to study size-dependent plasticity

[...] Read more.

Discrete Dislocation Dynamics (DDD) simulations are a powerful simulation methodology that can predict a crystalline material’s constitutive behavior based on its loading conditions and micro-constituent population/distribution. In this paper, a 3D DDD model with spiral dislocation sources is developed to study size-dependent plasticity in a pure metal material (taken here as Aluminum). It also shows, for the first time, multipole simulations of spirals and how they interact with one another. In addition, this paper also discusses how the free surface of a crystalline material affects the plasticity generation of the spiral dislocation. The surface effect is implemented using the Distributed Dislocation Method. One of the main results from this work, shown here for the first time, is that spiral dislocations can result in traditional Frank–Read sources (edge or screw character) in a crystal. Another important result from this paper is that with more dislocation sources, the plastic flow inside the material is more continuous, which results in a lowering of the flow stress. Lastly, the multipole interaction of the spiral dislocations resulted in a steady-state fan-shaped action for these dislocation sources.

Full article

(This article belongs to the Special Issue Deformation of Metals and Alloys: Theory, Simulations and Experiments)

►▼

Show Figures

Figure 1

Open AccessArticle

Coexistence of Intermetallic Complexions and Bulk Particles in Grain Boundaries in the ZEK100 Alloy

by

, , , , , , and

Metals 2023, 13(8), 1407; https://doi.org/10.3390/met13081407 - 06 Aug 2023

Abstract

Magnesium-based alloys are highly sought after in the industry due to their lightweight and reliable strength. However, the hexagonal crystal structure of magnesium results in the mechanical properties’ anisotropy. This anisotropy is effectively addressed by alloying magnesium with elements like zirconium, zinc, and

[...] Read more.

Magnesium-based alloys are highly sought after in the industry due to their lightweight and reliable strength. However, the hexagonal crystal structure of magnesium results in the mechanical properties’ anisotropy. This anisotropy is effectively addressed by alloying magnesium with elements like zirconium, zinc, and rare earth metals (REM). The addition of these elements promotes rapid seed formation, yielding small grains with a uniform orientation distribution, thereby reducing anisotropy. Despite these benefits, the formation of intermetallic phases (IP) containing Zn, Zr, and REM within the microstructure can be a concern. Some of these IP phases can be exceedingly hard and brittle, thus weakening the material by providing easy pathways for crack propagation along grain boundaries (GBs). This issue becomes particularly significant if intermetallic phases form continuous layers along the entire GB between two neighboring GB triple junctions, a phenomenon known as complete GB wetting. To mitigate the risks associated with complete GB wetting and prevent the weakening of the alloy’s structure, understanding the potential occurrence of a GB wetting phase transition and how to control continuous GB layers of IP phases becomes crucial. In the investigation of a commercial magnesium alloy, ZEK100, the GB wetting phase transition (i.e., between complete and partial GB wetting) was successfully studied and confirmed. Notably, complete GB wetting was observed at temperatures near the liquidus point of the alloy. However, at lower temperatures, a coexistence of a nano-scaled precipitate film and bulk particles with nonzero contact angles within the same GB was observed. This insight into the wetting transition characteristics holds potential to expand the range of applications for the present alloy in the industry. By understanding and controlling GB wetting phenomena, the alloy’s mechanical properties and structural integrity can be enhanced, paving the way for its wider utilization in various industrial applications.

Full article

(This article belongs to the Special Issue Advances in Lightweight Alloys)

►▼

Show Figures

Figure 1

Open AccessArticle

Optimization of Processing Parameters of Aluminum Alloy Cylindrical Parts Based on Response Surface Method during Hydromechanical Deep Drawing

by

and

Metals 2023, 13(8), 1406; https://doi.org/10.3390/met13081406 - 06 Aug 2023

Abstract

Aluminum alloy has been proposed as one of the next generation of lightweight body structure materials, which is widely used in the main components of the aerospace field. In order to realize efficient and accurate forming of aluminum alloy cylindrical parts, the response

[...] Read more.

Aluminum alloy has been proposed as one of the next generation of lightweight body structure materials, which is widely used in the main components of the aerospace field. In order to realize efficient and accurate forming of aluminum alloy cylindrical parts, the response surface method combined with finite element simulation was used to optimize the key processing parameters during the hydromechanical deep drawing process. Three processing parameters of friction coefficient, pressure rate, and fillet radius of the die were selected as the optimization variables, and the maximum thinning rate of cylindrical parts was selected as the optimization evaluation index. The Box–Behnken design was selected to design the experiment scheme. A quadratic response model between the maximum thinning rate and the processing parameters was established by the response surface analysis software Design Expert for experimental design and data analysis. The optimal processing parameter combination was obtained through this model. The results show that the optimal conditions of maximum thinning rate can be met when the pressure rate is 11.6 MPa/s, the friction coefficient is 0.15, and the fillet radius of the die is 8 mm. Finally, the experimental verification was carried out by using the optimized combination of process parameters. It was found that the error between the experimental results and the predicted simulation results was within 5%, and the cylindrical parts which met the quality requirements were finally formed.

Full article

(This article belongs to the Special Issue Plasticity and Metal Forming)

►▼

Show Figures

Figure 1

Open AccessArticle

Interfacial Stress Development and Cracking Susceptibility during Laser Powder Bed Fusion of Random TiB2-Particle-Reinforced AlSi10Mg Matrix Composites

Metals 2023, 13(8), 1405; https://doi.org/10.3390/met13081405 - 06 Aug 2023

Abstract

A sequentially coupled multi-phase thermo-mechanical model for laser powder bed fusion (LPBF) of Al-based composites reinforced by 1 wt.% random TiB2 micron particles was established. Due to the remarkable difference in thermophysical properties, the maximum thermal stress was predicted at the TiB

[...] Read more.

A sequentially coupled multi-phase thermo-mechanical model for laser powder bed fusion (LPBF) of Al-based composites reinforced by 1 wt.% random TiB2 micron particles was established. Due to the remarkable difference in thermophysical properties, the maximum thermal stress was predicted at the TiB2/Al matrix interface and formed at the liquid–solid transition stage. Meanwhile, complicated evolution curves of temperature, strain, and strain rate were predicted with the laser moving time during the solidification stage. To evaluate the interface cracking susceptibilities of micron-TiB2/AlSi10Mg composites, the flow stress of the matrix was calculated, instead of ultimate tensile strength, based on the physical constitutive relationship. From the comparison between the calculated flow stress and the simulated Von Mise equivalent stress, it was found that an increase in TiB2 particle size was inclined to induce a larger interfacial stress than the calculated flow stress, therefore increasing the interfacial crack tendency, which was also effectively verified by the experimental results.

Full article

(This article belongs to the Section Additive Manufacturing)

►▼

Show Figures

Figure 1

Open AccessArticle

Micro End Mill Capability Improvement Due to Processing by Fast Argon Atoms and Deposition of Wear-Resistant Coating

Metals 2023, 13(8), 1404; https://doi.org/10.3390/met13081404 - 06 Aug 2023

Abstract

Micro-milling is widely used to make micro-channels in various fields. In this study, micro-milling of rectangular bronze microchannels was carried out with carbide end mills with a diameter of 1 mm, processed with fast argon atoms, and coated with anti-friction wear-resistant titanium diboride.

[...] Read more.

Micro-milling is widely used to make micro-channels in various fields. In this study, micro-milling of rectangular bronze microchannels was carried out with carbide end mills with a diameter of 1 mm, processed with fast argon atoms, and coated with anti-friction wear-resistant titanium diboride. It was shown that the removal of a 3 µm thick surface layer from a micro end mill with fast argon atoms makes it possible to reduce the cutting edge radius of the tool to 1.2 µm, which is three times lower than the minimum value of 4 µm achievable in mechanical manufacturing. The subsequent deposition of a 3 μm thick anti-friction coating results in a wear-resistant micro end mill with original geometric parameters but improved performance. The surface roughness of the machined bronze microchannel significantly decreased, and the burrs above the groove practically disappeared after micro-milling.

Full article

(This article belongs to the Special Issue Tribological Properties and Surface Modification of Metallic Materials)

►▼

Show Figures

Figure 1

Open AccessFeature PaperArticle

Tempering Behavior of a Si-Rich Low-Alloy Medium-Carbon Steel

Metals 2023, 13(8), 1403; https://doi.org/10.3390/met13081403 - 05 Aug 2023

Abstract

►▼

Show Figures

Owing to the addition of Si, 0.33C-1.8Si-1.44Mn-0.58Cr steel exhibits a unique tempering behavior. The tempering takes place in two distinct sequential stages that are significantly different from those in steels containing 0.2–0.5 wt.% of Si. Stage I is associated with the precipitation of

[...] Read more.

Owing to the addition of Si, 0.33C-1.8Si-1.44Mn-0.58Cr steel exhibits a unique tempering behavior. The tempering takes place in two distinct sequential stages that are significantly different from those in steels containing 0.2–0.5 wt.% of Si. Stage I is associated with the precipitation of transition carbides in a paraequilibrium manner, can take place in temperatures ranging from ~200 to ~474 °C, and concurrently increases strength, ductility, and toughness. Stage II is associated with the decomposition of retained austenite to bainitic ferrite and transition carbides. As a result, no significant effect of overlapping of Stage I with Stage II takes place. Stage III does not occur at temperatures below ~474 °C, since the precipitation of cementite in a orthoequilibrium manner is suppressed by the addition of 1.8 wt.% of Si. It was shown that a major portion of carbon atoms redistributes to Cottrell atmospheres under quenching. During low-temperature tempering at 200–400 °C, the precipitation of transition carbides consumes a large portion of carbon atoms, thereby increasing the number of ductile fractures and improving the impact toughness without strength degradation. The formation of chains of cementite particles on boundaries takes place in Stage IV at a tempering temperature of 500 °C. This process results in the full depletion of excess carbon from a ferritic matrix that provides increased ductility and toughness but decreased strength.

Full article

Figure 1

Journal Menu

► ▼ Journal Menu-

- Metals Home

- Aims & Scope

- Editorial Board

- Reviewer Board

- Topical Advisory Panel

- Photography Exhibition

- Instructions for Authors

- Special Issues

- Topics

- Sections

- Article Processing Charge

- Indexing & Archiving

- Editor’s Choice Articles

- Most Cited & Viewed

- Journal Statistics

- Journal History

- Journal Awards

- Society Collaborations

- Conferences

- Editorial Office

Journal Browser

► ▼ Journal BrowserHighly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Topic in

Minerals, Metals, ChemEngineering

Advances in Sintering and Pellet Technology

Topic Editors: Rajesh Kumar Jyothi, Rafael Santos, Shivakumar Angadi, Sanjay AgarwalDeadline: 31 August 2023

Topic in

Applied Sciences, Coatings, JMMP, Materials, Metals

Welding and Joining of Materials in Off-shore and Energy Industry

Topic Editors: Dariusz Fydrych, Jacek Tomków, Aleksandra Świerczyńska, Grzegorz Rogalski, Sergey G. Parshin, Chandan Pandey, Michał Landowski, Hamed Aghajani Derazkola, Thomas HasselDeadline: 15 September 2023

Topic in

Applied Sciences, Coatings, CMD, Materials, Metals

Environmental Sensitivity and Safety Assessment of Materials

Topic Editors: Jian Chen, Daokui Xu, Fanjiang Meng, Jamie NoëlDeadline: 30 September 2023

Topic in

Applied Sciences, Coatings, Materials, Metals, Nanomaterials

Cutting-Edge Research Trends in (Non)Metallic Materials: Design, Testing and Application

Topic Editors: Petrica Vizureanu, Andrei Victor Sandu, Madalina Simona Baltatu, Dumitru Doru Burduhos NergisDeadline: 31 October 2023

Conferences

27 October–10 November 2023

The 4th International Electronic Conference on Applied Sciences (ASEC2023)

Special Issues

Special Issue in

Metals

Advanced Manufacturing of Novel Metallic Related Materials

Guest Editors: Victor A. Klinkov, Vera PopovichDeadline: 10 August 2023

Special Issue in

Metals

Additive Manufacturing of High Temperature Alloys

Guest Editors: Vera Popovich, Ehsan HosseiniDeadline: 25 August 2023

Special Issue in

Metals

Recovery of Valuable Metals from Industrial By-Products

Guest Editors: Sun-Joong Kim, Xu GaoDeadline: 31 August 2023

Special Issue in

Metals

Effect of Ultrasound on the Structure and Properties of Metallic Materials

Guest Editor: Ayrat NazarovDeadline: 15 September 2023